What is Reverse Engineering Services?

Reverse Engineering Services is the process of creating the design drawings from a physical object by taking manual measurements or scanning the product with the help of a laser scanner. It involves creating detailed CAD drawings and models with acceptable tolerance from the existing parts and assemblies. This is useful for making improvements in an existing product or assembly and in cases where there is insufficient CAD documentation required for modern methods of manufacturing.

Benefits:

- The CAD model can be used to study, inspect, analyze, reproduce, troubleshoot or can be used for future product enhancements and applications.

- Changes in the product design can be updated easily in the 3D CAD models.

- Surface models created by Vaarpu can be used to create Tools and Dies.

- 3D Reverse Engineering Services can be used to fix broken parts wherein we create a CAD model with the broken part fixed. This can be used to fix the broken part quicker.

Reverse Engineering Services for Diverse Verticals and Industries

- Automobiles

- Heavy Machinery

- Industrial Plants

- OEM and Equipment manufacturers

- Building Products manufacturers

- Wood & Metal Furniture manufacturers

- Fabricated Metal & Alloy manufacturers

- Oil & Gas

Key Differentiators

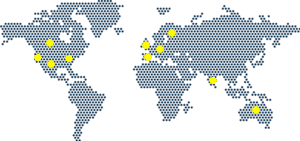

Benefit from Vaarpu engineering experience by Outsourcing Reverse Engineering Services to the most trusted 3D Reverse Engineering Service providing Company. This will help you to:

- Modernize your manufacturing process

- Precise Surface Modeling

- Create a new design

- Receive CAD data that represents the object’s original design intent

- Remove and remanufacture a defective part